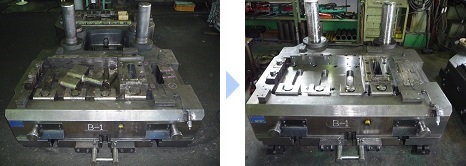

Overhaul of forging press die holders

Flow of order to delivery for overhaul and modification

- 1. Presentation of the intended weight (metric ton) of the die holder (with fabrication drawing attached)

- 2. In case where no fabrication drawing, hand drawing or CAD drawing is available, discussion is held about the potential use of old materials, modification processing, and new manufacturing using actual material or newly created drawings.

- 3. Confirmation of estimate specification based on desk research

- 4. Presentation of a rough estimate based on desk research

- 5. Discussion about order

- 6. Receipt of tentative order

- 7. Taking-over of subject material

- 8. Disassembly and cleaning check

- 9. Matching with specifications based on desk research (a couple of days needed)

- 10. Verification of overhaul specification

- 11. Making up a formal quotation based on the verified specification (on 3rd day)

- 12. Acceptance of purchase order

- 13. Correction of subject material

- 14. Correction of parts (on 6th day)

- 15. Assembly using newly created parts (on 8th day)

- 16. Assembly test (on 9th day)

- 17. Shipping (on 10th day)

References to be presented

- Component list

- Material milling sheet

- Heat treatment inspection list

- Parts processing inspection list

- Assembly test list

*The presented references listed above represent a history management data for customers' production tools.

In addition, Uchida has a special discount service for our registered customers to order repeated overhaul.

3000TON die holder accuracy update processing

3500TON die holder accuracy update processing

6300TON die holder accuracy update processing

Our Serveces

About Us

Back to